Portamus INTERVIEW

The craft behind the finest backpacks

We are back with a brand new ‘Meet the Maker’, a feature that is so important to us at SGB. With all our products being handmade, by talented craftsmen and women over the length and breadth of almightily Blighty, we feel it is our duty to share with you who our makers are along with an insight into their craftsmanship and brand journey.

SGB: Let’s jump right in, today we welcome Ben the founder and head maker at Portamus: a premium outdoor bags company based in Gloucestershire. So Ben, what inspired you to get Portamus up and running?

Ben: So before Portamus, I worked for such a variety of brands both big and small for over 20 years and I’d say this was my inspiration. I wanted to create something using all the best components and knowledge that I had discovered over the years. I am passionate about quality and often quality materials, such as the ones used in my own products, get downgraded in the pursuit of margin and I've been determined to not let that happen. So, the belief that I could create something special was a big inspiration and then teaming that with my love of the outdoors was a natural route to take.

SGB: With the inspiration in the bag, what did it take to go from your initial passion to the reality that is Portamus?

Ben: Gosh - A lot of hard work! It's the component development that takes time. And then a lot of trial and error. You'd be amazed at the difference an extra 1mm in length of a rivet prong can make!

SGB: Where does the brand name ‘Portamus’ come from?

Ben: Ha! Well, Portamus means 'we carry' in Latin. I know this because when I was 12 I wasn't listening in school and was made to write out 100 lines of Porto, Portas, Portat, Portamus, Portatis, Portant. In traditional fashion, the lines were not even looked at but thrown straight in the bin. However, I have now reclaimed the experience! I have made those lines worthwhile! (Not that I can remember anything else at all from Latin lessons.)

SGB: It’s clear that you are passionate about accessory making, enough so as not to be put off by an extra 1mm here and there, where does your love for accessory making come from?

Ben: Ah honestly it's a bit random...It's 1993, I'm at high school in Worcestershire and I desperately want to be Miles Hunt from The Wonder Stuff. I then make the obvious decision to sign up for Textiles as a subject just so that I can make a three-piece tartan suit. Viola - Miles Hunt impersonation complete but more importantly I'd learnt to sew and create. Within a year, I was selling my clothes and accessories via small local independent shops.

SGB: Miles Hunt opts for a career change then, aha! You mentioned earlier that quality was a driving force behind the brand. We’re interested to find out a bit more about your stance on sustainability?

Ben: Yes so first of all it is about quality. At the end of the day, products that are made to last are the most sustainable. So whilst we do try to source locally and use natural materials that avoid nasty chemicals, it's the quality and longevity that is our main focus. I really don't want people to buy twice!

SGB: Obviously, this can pose challenges. How do you find being a ‘slow fashion’ accessories brand in a world of mass production and consumption?

Ben: To be honest it's a great relief. The focus for us is on quality and getting details right rather than trying to convince the public that they need our new bright shiny seasonal product because it will in some way bring them fulfilment. Our people will find us, and we will find them, all in good time.

SGB: We’re quickly learning that quality is the key, could you tell us a bit about your chosen material and perhaps about the sourcing of these materials?

Ben: We're not shy about talking about our sources. In a nutshell, we try to source locally where we can but with an eye for quality, we do sometimes need to reach out a little further. By following that principle all our fabrics are woven and finished here in the UK and the leather comes from Tuscany, (British tanneries produce some fantastic products but with not quite the right performance characteristics that we needed) from a lovely family-run small tannery in Santa Croce.

SGB: Let’s talk design, what does your design process look like?

Ben: It’s a process of osmosis and collection, I collect details, colours, thoughts even. They get pinned on walls, stuck in books or filled away, but I never forget where they are. And then one day I'll think.."Yes! That swatch I picked up 5 years ago on a tannery visit would be just perfect!" It's certainly a slow process, let’s leave it at that.

SGB: With the heritage feel of your bags, where does the inspiration for their design come from?

Ben: I have a picture in my mind of a French resistance fighter crossing the Pyrenees on a dark snowy night. It's quite an evocative isolated image and I have no idea where it came from. Probably just from watching too many war movies but it's an image teamed with my love of vintage fashion that steers the look. Aside from this, it is important to note the inspirations for my designs lie with people, history and emotions.

SGB: Are there any other makers/designers who inspire you?

Ben: Absolutely. I'm very lucky to be based in the Stroud valley's where there is an awe-inspiring network of designers and makers. We're all a constant source of inspiration and encouragement to each other.

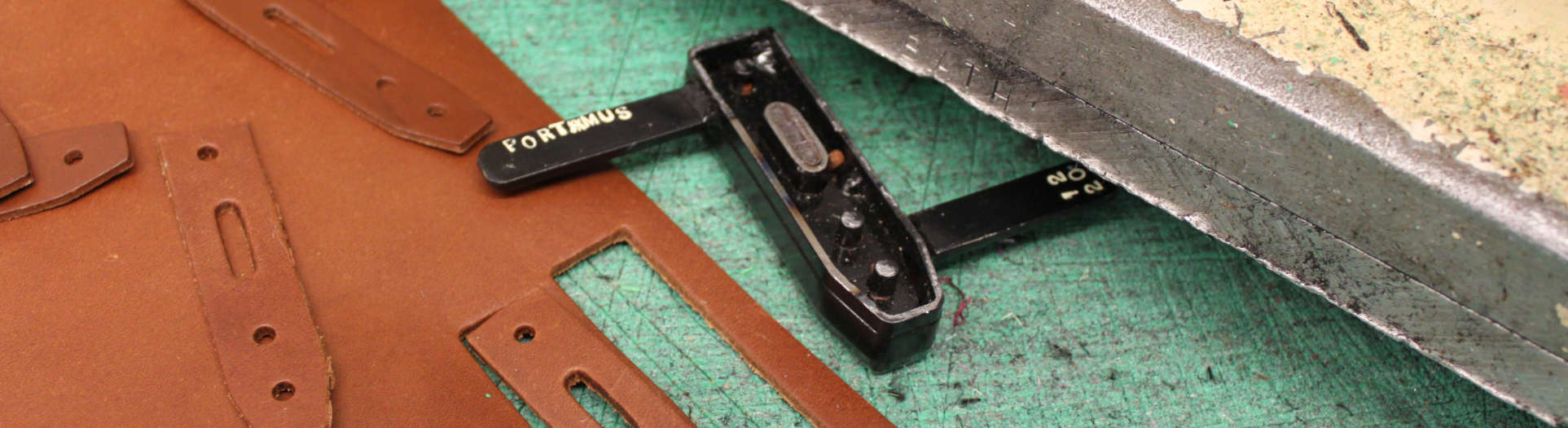

SGB: Moving on from design, what craftsmanship skills do you use when making the bags?

Ben: It's a real mix from pattern cutting, to leather edge polishing, to the intricacies of operating the machinery. I'm really lucky to work with and have worked with a real mix of very talented craftspeople from tailors in Savile Row to leather cutters in Calcutta. They've all had such an impressive knowledge of their trade and I've never been coy about trying to learn as much information as I can from them.

SGB: All of Portamus bags are handcrafted by yourself, how do you think this impacts the final product?

Ben: By having one person work on a product from start to finish, it gains a certain form of wholeness. Somehow all the elements just fit together properly and feel as if they are where they are meant to be - Sounds a bit cheesy, I know!

SGB: What is your favourite stage of the manufacturing process?

Ben: Easy. The ‘turning out’. You make 95% of a bag inside out and one of the last processes is to 'turn it out'. Instantly, you can see what it looks like. Although, this is my favourite process it can be frustrating as sometimes this is when you realise you've stitched the zip in upside down!

SGB: Which of your tools is your personal favourite?

Ben: My new strap cutter, I cannot wait to start using it.

SGB: Being a maker comes with its challenges, what has been the biggest challenge that you’ve faced during your creative journey?

Ben: Funding and time, I’m never short of ideas. Just sometimes a little short of those two important factors that make it possible.

SGB: Finally, is there anything exciting in the pipeline for Portamus?

Ben: Lots of new product ideas but really it's all about getting the word out there. We're on a mission to find our people. We don't want to be any bigger than is manageable and when you make a product like we do that's actually pretty small, perhaps even exclusive!